Coolant Caps

PIONEER Coolant Cap System is available for ER, TG & SX Collet Chuck Systems

What is required:

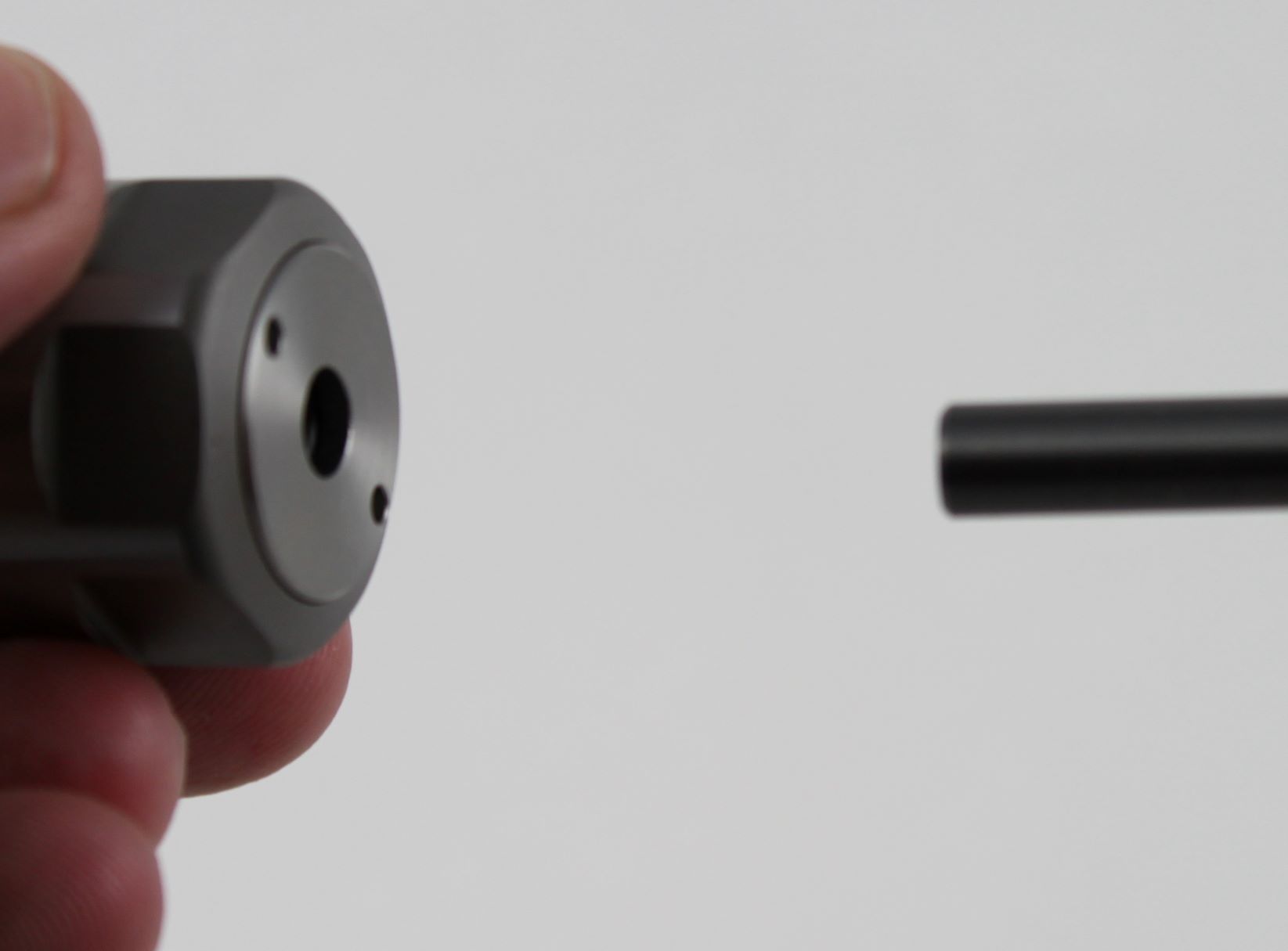

- Cutting Tool Shank that is the length of the collet + 1/4" (6mm) to provide a surface to seal against

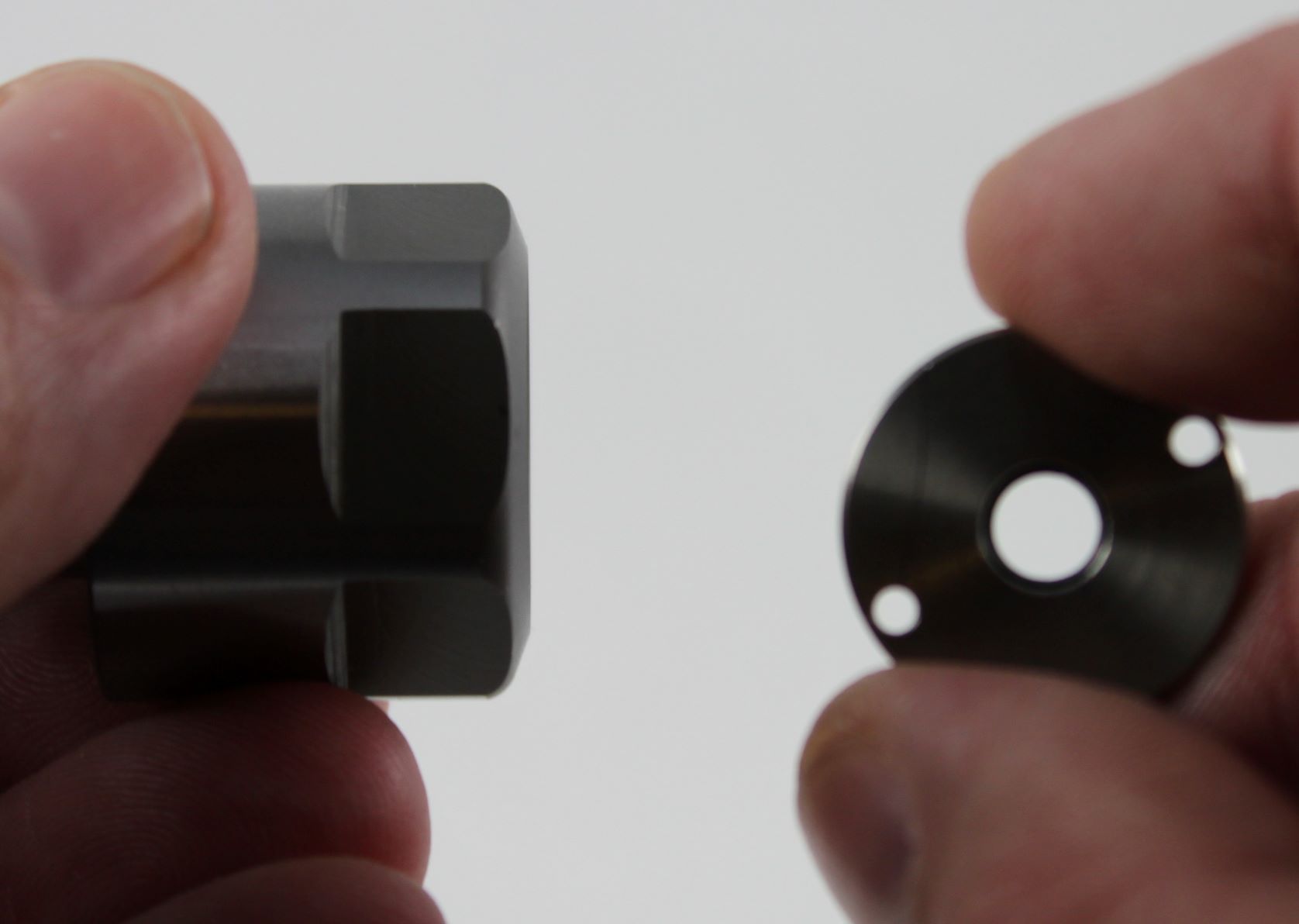

- Coolant Cap Nut

- Coolant Cap to fit Cutting Tool Shank

- Coolant Cap Wrench

- Thread Coolant Cap into the nut. Do not tighten, leave cap loose.

- Insert cutting tool with the seal engaged on the round portion of the cutter shank.

- Snug Cap.

- Insert assembly into the collet chuck, tighten per instructions.

- Do not over tighten!

Using Coolant Caps with Taps & Short Shank Cutting Tools

It is possible to seal taps for high pressure coolant thru operations. The success or failure is dependent on the tap length and flute lengths ground into the tap.

Using Coolant Caps

The Coolant Cap will seal the Cutting Tool Shank if there is at least 1/4" (6mm) to provide a surface to seal against.

This position allows the o-ring of the cap to seal against the shank.

From our research tap manufacturer's are anything but consistent. There are hundreds of shank and square combinations, relief grind lengths very inconsistent batch to batch this makes sealing taps more difficult than it needs to be.

Long tap shanks is the best condition for using coolant caps and sealing for high pressure coolant up to 750psi.

When Coolant Caps do not work

Both taps below are standard 1/2 hand taps. If you look at the flute on the top picture it extends into the collet. The picture on the bottom the flute stops just before the front of the collet. This leaves no surface for the seal to engage.

These tap flute designs effect both Coolant Caps and some Sealed Tap Collets.